Practical 3: Friction and Minor Losses in Pipes

Calculations

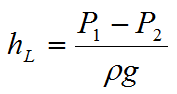

For all of the calculations in this practical you will need to convert the pressure difference into a head measured in metres:

Where P1 and P2 are respectively the upstream and downstream pressure in Pascals.

Major Losses

You will be using the observed head loss hf to determine the friction factor λ and hence the relative roughness (k/D) for each pipe. Then you will compare the absolute roughness (k) with typical roughness values for each pipe material (you can find such values in textbooks or on the internet).

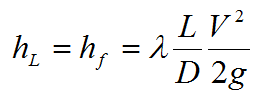

We’re assuming that the entire pressure difference is due to friction in the pipe. So the observed hf can also be given by the Darcy equation:

As you know hf, L, D and V (which you can get from the flow rate and diameter using the continuity equation), you can rearrange this equation for the friction factor λ. For each pipe, three flow rates were passed through the system so you will need to perform the calculation three times to get three different values of λ.

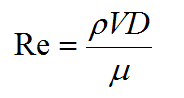

To obtain the relative roughness (k/D) you also need the Reynolds number (Re):

You can assume the dynamic viscosity (μ) is 1.005 x 10-3 kg/ms.

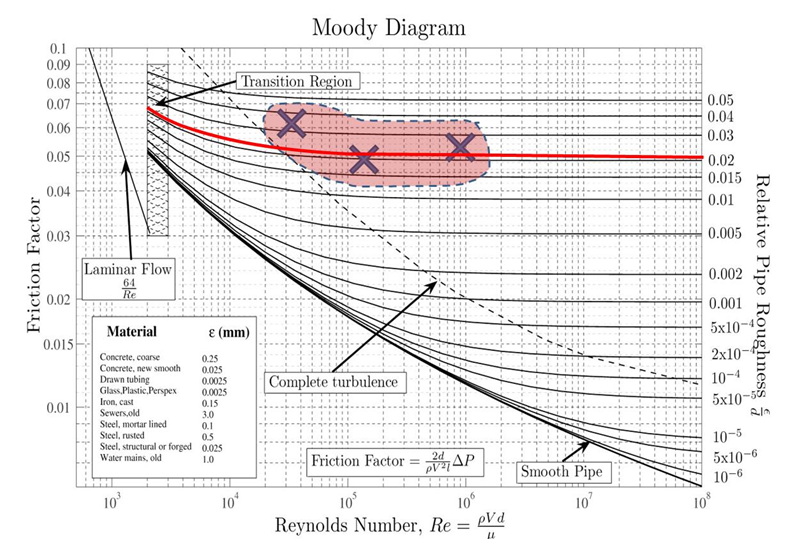

Now you have two options to obtain k/D. One is to plot the values of λ and Re on the Moody diagram above.

Once you have plotted your three points on the Moody diagram, you can estimate an “average” curve (see the red line in the example diagram) that follows the same basic shape as the other curves on the chart. (Note that it is very common in this experiment for results to be spread out such that the average curve does not pass neatly through all three points. In these cases you could also plot an upper and lower curve to capture the “spread” of the results.) The point where your average curve exits the chart on the right is where you can infer the value of relative roughness. If you have plotted an upper and lower curve to capture a wide spread of results, you can infer an upper and lower value of k/D accordingly.

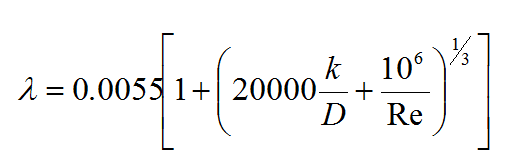

The alternate method is to rearrange the Moody equation to determine k/D. The Moody equation is used to generate the lines on the Moody diagram so you will get a more accurate result by using the equation directly. The equation is as follows:

It is straightforward to rearrange this to obtain k/D in terms of Re and λ.

Minor losses

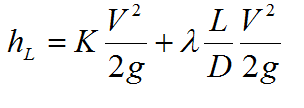

In the case of the minor losses, the observed head loss is due to the loss in the object itself plus pipe friction:

You have been given the length between the two tapping points, the flow rate and the observed pressure difference (which you convert to hL). The minor loss experiment was conducted in 25mm galvanised steel pipe, which means you have can determine velocity.

You will need to refer to your calculations from the Major Losses part of the experiment in order to determine an appropriate value for λ. You can either calculate λ using the Moody equation (or diagram) from the k/D value you obtained earlier for galvanised steel, or, if the velocity in the minor loss experiment is quite close to one of the velocities used in the major loss experiment (for 25mm galvanised steel) you might simply use the value of λ from that experiment.

Once you have a value for λ, the only unknown in the equation is the head loss coefficient K. You can therefore determine a value of K for each object and compare these against typical values for each device (you can find published values in textbooks or on the internet).